Canola Oil Transload Facility

Project Description

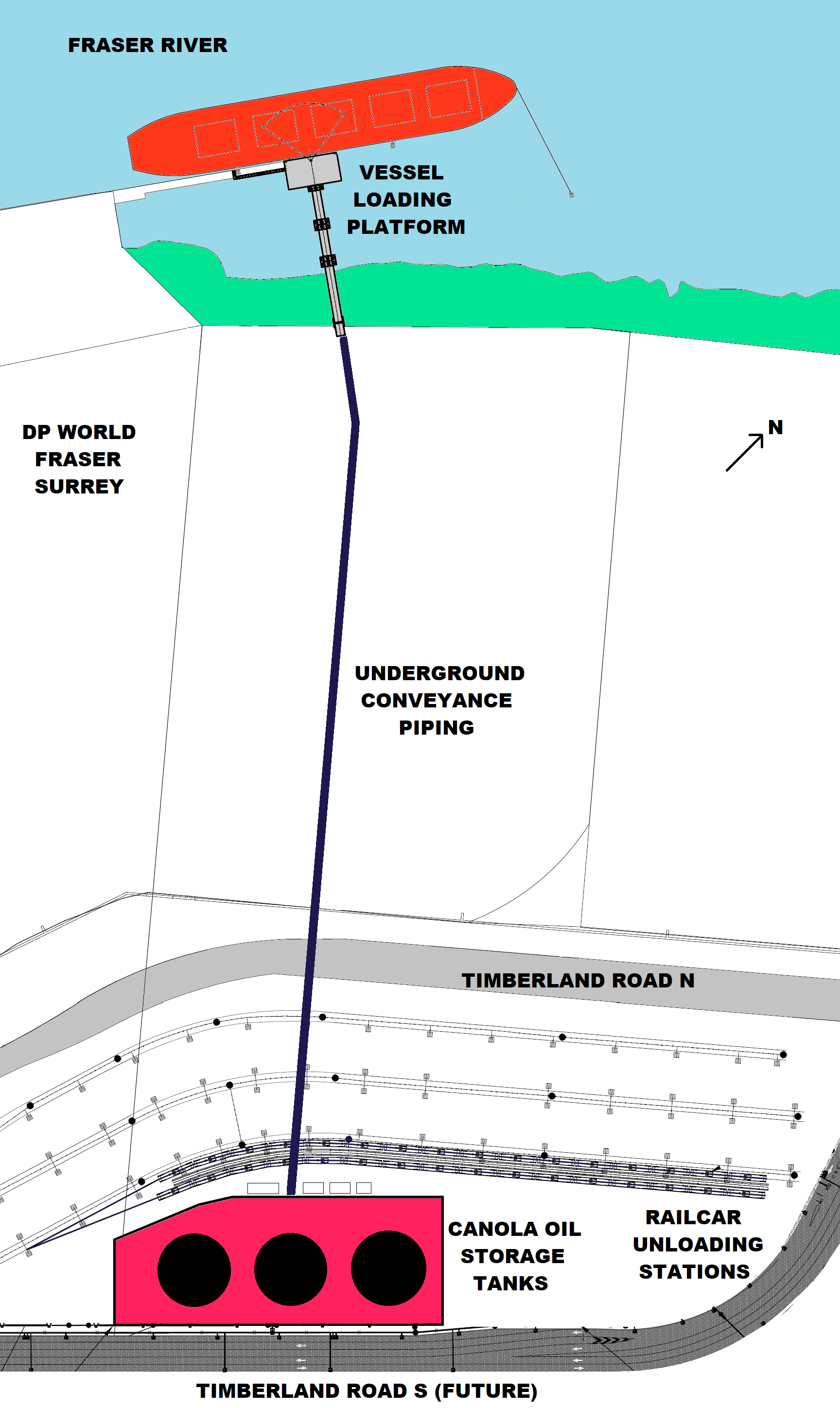

DP World Fraser Surrey Inc. proposes to redevelop a portion of their existing Fraser Surrey Terminal and Berth 10 located at 11060 Elevator Road, Surrey, BC to function as a canola oil transload facility. Redevelopment would result in a canola oil throughput capacity of approximately 1,000,000 tonnes per year.

The Project broadly consists of the following components:

- Canola loadout terminal at Berth 10, including construction of a concrete marine access trestle, loading platform, and a catwalk connection between Berths 9 and 10 supported by roughly 28 piles total (approx. 35 in-water)

- Construction of ancillary loading deck and platform infrastructure, such as a marine loading arm and upgraded marine bollards and fenders

- Installation of two rail spur tracks (one replacement, one new) for rail receiving and unloading, including construction of railcar bottom offloading stations, unloading pumps, piping and control cables

- Three carbon steel 15,000 metric tonne capacity storage tanks (18m high, 37m diameter)

- Elevated tank foundations, with associated ground improvement works

- Vessel loading pumps

- Containment area with liners, precast walls, and foundations; and

- New fire water loop with six hydrants

- Installation of below grade canola oil transmission and recycle lines to connect storage tanks to the marine trestle

- Development of ancillary facilities including, control building, Motor Control Centre, security facility and vehicle parking

- Various associated utility installations, relocations and removals

The Vancouver Fraser Port Authority Project and Environmental Review Permit (PER No. 22-017) was approved of May 2nd and related information is available through the links below.